Welcome to Shandong Xinqiujing Metal Material Co., Ltd.

Tel : +8617353827712 Email:sdxinqiujing@sdxinqiujing.com

PRODUCT CENTER

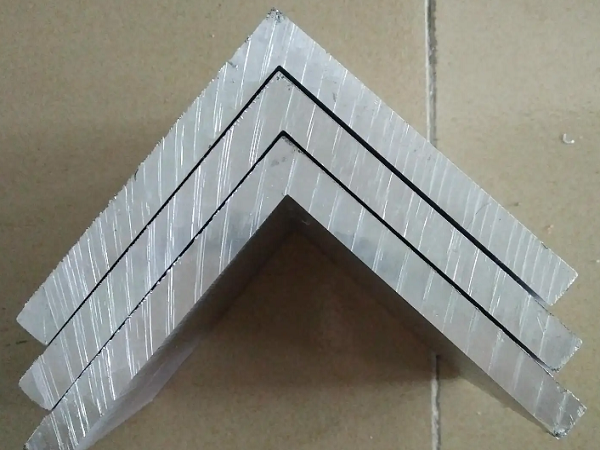

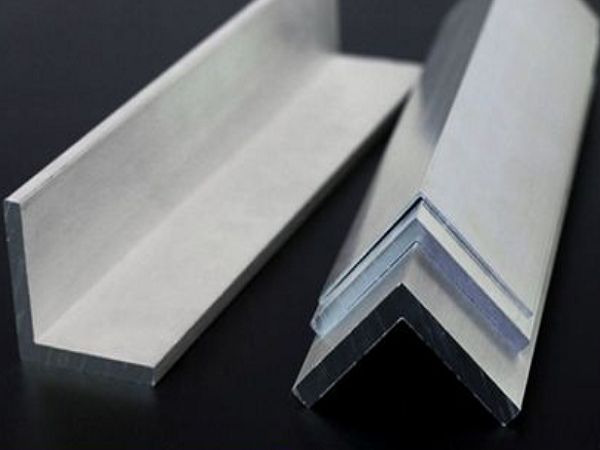

6063 T5 Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters

6061 H112 Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters

1100 H16 Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters

1060 H14 Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters

1050 H112 Angle aluminum is an aluminum profile with two perpendicular intersecting edges, which is L-shaped and has sides ranging from ten millimeters to one or two hundred millimeters in length and thicknesses ranging from one millimeter to several tens of millimeters

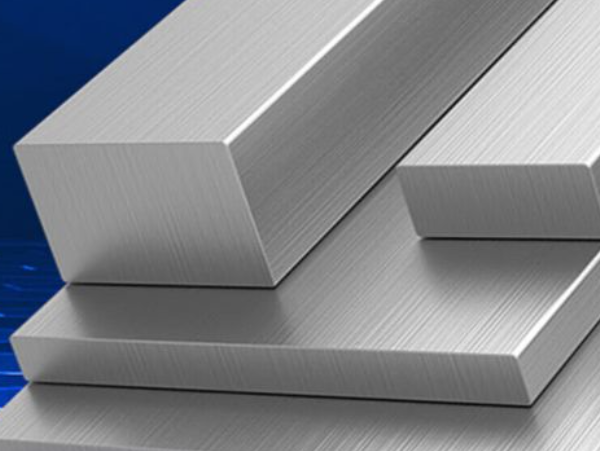

6063 T5 aluminum flat bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

6061 H112 aluminum flat bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

1100 H112 aluminum flat bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

1060 H12 aluminum flat bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

1050 H14 aluminum flat bar are mainly used in electrical engineering such as high and low voltage electrical appliances, switch contacts, distribution equipment, bus ducts, etc. As a conductive bus, they have the advantages of low resistivity and high flexibility.

Processing multi sided glass bodies requires a multi sided glass body grinder or grinder. And these grinding machines must also be equipped with a sufficient number of fixtures for bonding workpieces, commonly known as "aluminum rows", in order to ensure product quality and fast production efficiency.

MAIN PRODUCTS

PROVIDE YOU WITH FREE SOLUTIONS